🇳🇱 ASML Holding N.V. – A Shrinking Expansion 🇳🇱

Research shows that only a few high-performing companies create the entire global net wealth.

Discearn is on a mission to find and dissect them.

In this post, we zero in on ASML – a truly unique Dutch giant of microchip production.

***

ASML sells machines which generate light you can only find in space to pattern the finest details on the most sophisticated chips.

The technology is so advanced that the company is essentially a monopoly.

The future of exponential digitization rests on this stand-alone linchpin, making it one of the most important companies no one has ever heard of.

It has an insane moat, dizzying scale, and enjoys strong structural tailwinds.

But it must now play a complicated geopolitical chess game, dance around the swift decoupling and tackle the Russia’s-invasion-induced pressure on supply chains.

Can it thrive in such turbulent times?

And would you buy the stock, if the person you love most had to rely on it for retirement?

Let’s dive in and find out..

The Macro Backdrop

Semiconductors – or small chips made of silicon to conduct electricity – are ever-more ubiquitous in our lives.

They can be found in thousands of products we all use daily.

And supply chain disruptions have made it clear that these mighty devices form the backbone of the digital economy.

Going forward, they will be critical to all key industries, ranging from quantum computing to military security.

Currently, the entire industry is enjoying profound tailwinds:

🇳🇱 The demand for chips seems insatiable.

🇳🇱 Advances in artificial intelligence, 5G, virtual reality, gaming, and data centers and storage are but a few megatrends fueling the growth across the sector.

🇳🇱 The electronics industry is booming. We are likely to go from 40 billion connected devices in use today to 350 billion in the next ten years.

🇳🇱 Mobile and sensor-enabled applications and services are growing fast, increasing reliance on distributed computing and storage solutions.

🇳🇱 As governments reduce geographical dependencies and increase technological sovereignty, the US, China, the EU, as well as Japan and South Korea are projected to invest heavily in the segment by doubling the industry’s 2021 annual capital expenditures of $150 billion.

Simply put, there will be a lot more chips in ten years.

Foundries will likely need to spend more money on equipment to cater to this enormous demand.

And Wall Street forecasts that the entire industry will generate $1 trillion in revenue by 2030, more than double the 2018 levels of $466 billion.

***

It’s important to note that the process of fabricating chips is complex.

It involves a global semiconductor ecosystem, including infrastructure suppliers, companies specialized in chip design and equipment and chipmakers themselves.

Businesses in this space are certainly interesting, profitable, rapidly growing, yet susceptible to cyclical swings and political turmoil.

And there is one company that really stands out from this crowd, as it is essentially a monopoly.

Enter ASML..

A Dutch enterprise which leads the way in manufacturing complex lithography machines that pattern the finest details on the most advanced microchips.

Over the years, it has been able to develop a unique, cutting-edge technology others simply could not master.

And now it stands on its own, as both a runaway behemoth and a linchpin in the semiconductor supply chain.

In the long run, the confluence of the industry tailwinds coupled with an insane moat and further R&D-induced advances, could, geopolitical conundrums notwithstanding, supercharge ASML’s growth further.

Top hedge fund managers eye this company closely.

The four letters are on the lips of Xi Jinping, Ursula von der Leyen, Joe Biden and other key players in the geopolitical chess game of the great decoupling.

Yet, it is hardly a household name outside these circles.

As Lawrence Burns of Baillie Gifford fame put it, “it’s probably the most important tech company people have never heard of”.

So in the self-proclaimed year of the stock picker, this post will zero in on all things ASML and walk you through the “guts of the business”.

Investment Thesis

Semiconductors are already everywhere but there will be a lot more of them in 10 years as they are instrumental to all industries of the future.

Every time there is an adoption of a new digital model or greater digitisation, it means more business for ASML.

ASML is a de facto monopoly as it mastered a technology so complex no one else comes close.

The company is also advancing through effective R&D spending, so the unique competitive position appears to be a long-term opportunity.

In a low market scenario, we are looking at 3-year revenue growth of 29 per cent. In a high market scenario, it can hit 61 per cent.

Investment Anti-Thesis

In light of ASML’s markets and a large number of suppliers it relies on for assembling the machines, a note of caution pertains to the geopolitical whirlwinds, the changing world order and a potential bifurcation into an axis of irredentist autocrats and a declining west with all the second-order consequences of decoupling and added pressure on supply chains.

The semiconductor industry can be cyclical and ASML is ever-exposed to any potential downturn.

Increased pressure on know-how and IP protection for ASML means unauthorized disclosure can benefit competitors and affect ASML’s ability to file patents.

Company Profile

ASML was founded in 1984.

Since then, it has grown from a small startup to a multinational colossus.

It has a market cap of roughly $268 billion and employs 33,000+ people in 60 locations across 16 countries in Europe, Asia and the US.

In a paradigmatic fashion, it did not make it here in a straight line.

There were many early twists and turns and the initial struggle, bankrolled by a nearly bankrupt Phillips was nothing short of a Silicon Valley start-up-type of a miracle.

Somehow, even in the early days key decision makers understood the importance of the underlying technology and persevered through the struggle.

Now, in simplified terms, ASML makes complex lithography machines that chipmakers use to produce semiconductors.

In essence, leading-edge microchips contain billions of transistors.

And with each new generation (referred to as a ‘node’), more and more transistors need to be packed in to make them faster, more powerful, and energy efficient.

This is where the pursuit of Moore’s Law (which states that every two years the number of transistors on a microchip double, while at the same time the price of computing is halved) plays out.

To continue past the 5-nanometer process node, chipmakers need to have the next-generation lithography tools from ASML. There is simply no way around it. These are the only machines that can pattern the required complicated details on such nanoscopic scale.

James Anderson, who is arguably one of the best stock pickers of all time, went so far as to claim that without the extreme ultraviolet technology that ASML has developed (more on that below), Moore’s Law would effectively come to a halt.

He then went on to argue that it makes ASML the most important company in the world.

ASML’s portfolio of products and services is both impressive and well-diversified.

It covers every phase of bringing a chip to market, from R&D, through each step of the manufacturing process, all the way to mass production.

Their products are used at every major semiconductor manufacturer you can think of, from Intel, Samsung, to TSMC.

The company rests on five pillars:

Strengthening customer trust

Holistic lithography and applications

DUV competitiveness

EUV 0.33 NA for manufacturing

EUV 0.55 NA insertion

All of these will become clear, as we progress to unpack what the company is all about.

ASML defines its purpose as:

unlocking the potential of people and society by pushing technology to new limits.

The vision is to:

enable groundbreaking technology to solve some of humanity’s toughest challenges.

The mission is summarized to:

provide leading patterning solutions that drive the advancement of microchips.

How Does the Company Make Money (Products and Services):

Simply put, ASML makes money by:

selling lithography equipment (73.4 per cent of net sales), and

providing services and upgrade options (26.6 per cent of net sales).

The machines can be divided into the following categories (and we will unpack all of them below):

Extreme Ultraviolet Systems (EUV)

Deep Ultraviolet Systems (DUV) comprising:

*Immersion Systems

*Dry Systems

Metrology and Inspection Systems comprising:

*Optical metrology

*E-beam metrology and inspection

*Systems and process control

*Computational lithography.

In 2021, ASML sold a total of 309 lithography systems (up from 258 in 2020). The breakdown per category looked like this:

42 EUV Systems (33.8 per cent of all net sales)

81 Argon Fluoride Immersion Systems (26.6 per cent of all net sales)

22 Argon Fluoride Dry Systems (2.3 per cent of all net sales)

131 Krypton Fluoride Systems (7.1 per cent of all net sales)

33 I-Line Systems (0.8 per cent of all net sales).

Total revenue for all system sales, including metrology and inspection amounted to €13.6 billion (up from €10.31 billion in 2020).

Net service and field option sales amounted to €5 billion (an increase from €3.7 billion in 2020).

ASML’s biggest markets are:

Taiwan (39.4 per cent)

South Korea (33.4 per cent)

China (14.7 per cent) and

The US (8.5 per cent).

Extreme Ultraviolet

Let’s start with explaining the EUV or ‘extreme ultraviolet’ systems.

This is the biggest and most important part of ASML’s cash cow.

It’s also where the moat magic plays out.

EUV systems contributed 31.9 per cent of sales in 2020 and 33.8 per cent of sales in 2021.

In general terms, the long-term growth of the semiconductor industry is based on the principle that the energy, cost and time for electronic computations can be reduced by shrinking transistors on microchips.

And one of the main drivers behind shrink is the resolution that lithography systems can achieve.

This is determined by:

the wavelength of the light used and

the numerical aperture (NA) of the optics.

A shorter wavelength – like a more sophisticated brush used for a painting – can print ever smaller features on a chip.

A larger numerical aperture can focus light more tightly, leading to better resolution.

Extreme ultraviolet refers to the light’s wavelength.

The light used in EUV lithography has a wavelength of just 13.5 nm and a numerical aperture of 0.33.

Such light only naturally occurs in space.

But ASML has the ability to harness it inside their sophisticated machines.

This wavelength is reduced almost 15 times when compared to the next most advanced lithography solution.

So just to illustrate, the deep ultraviolet (DUV) light used in argon fluoride (ArF) lithography has a wavelength of 193 nm.

To generate EUV light, a carbon dioxide laser fires two separate laser pulses at a fast-moving drop of a tin. This vaporizes the tin and creates EUV light.

It does this up to 50,000 times per second.

These systems are used in high-volume manufacturing to create the highly complex foundation layers of the most advanced microchips (7, 5 and 3 nm nodes).

For example, an advanced Logic chip at the 3 nm node is made up of about 80 layers.

Around 26 of these are printed using EUV.

The rest of the layers are printed using various DUV systems.

Both types of technology will be required in parallel for many years to come and ASML continues to advance both technologies.

Using EUV makes scaling more affordable and helps reduce significant defect, cost and cycle time.

ASML expects that the adoption of EUV will continue to grow and that all advanced node chipmakers will use EUV in their production by 2024.

And speaking of moat, if there ever was one, currently EUV lithography is a technology entirely unique to ASML.

Other companies also produce lithography systems but ASML’s cutting edge EUV platform is the absolute top dog in the game. No one really comes close.

And for a good reason.

Developing EUV was anything but a breeze.

ASML invested more than €6 billion in EUV R&D over the course of 17 years.

It also acquired a company called Cymer which specialized in light source technology.

And once the technology was developed, ASML had to surmount numerous technical challenges to meet the requirements of high-volume production.

They persevered through it all and are now reaping the benefits.

Pierre Ferragu, an Analyst at New Street Research noted that this technology “is the most difficult to replicate”. Others estimate that it would take rivals a decade to catch up. By then ASML will have moved on with better optics.

Currently, ASML offers two EUV systems.

The first is the TWINSCAN NXE:3600D.

It is ASML’s latest-generation lithography system, supporting EUV volume production at the 5 and 3 nm Logic nodes and leading-edge DRAM nodes.

The second is the TWINSCAN NXE:3400C lithography system which supports EUV volume production at the 7 and 5 nm nodes.

Each EUV machine weighs 180 tonnes, has approximately 100,000 moving parts, two kilometres of cabling and costs more than $150m.

ASML sells them to the likes of TSMC, Samsung and Intel.

Chinese manufacturers are also very keen to buy them too.

The Dutch company sold 42 EUV systems in 2021 and projects to sell 75 in a high market scenario in 2025.

Since its introduction, ASML’s EUV systems produced more than 59 million wafers by end of 2021, relative to 26 million wafers produced by end of 2020.

Deep Ultraviolet

The second biggest business is DUV.

These systems produce the majority of layers in a chip.

ASML offers a whole range of products here, including immersion and dry lithography solutions for all DUV wavelengths currently used in the industry, namely:

I-line using the 365 nm wavelength,

Krypton Fluoride (KrF) using 248 nm and

Argon Fluoride (ArF) using 193 nm.

This segment was responsible for 36.8 per cent of net sales in 2021.

Immersion Systems:

Immersion lithography uses a pool of ultra-pure water between the lens and the wafer to increase the lens's numerical aperture (NA).

With conventional dry lithography, NA can only reach about 0.93. Immersion made it possible to create systems with an NA up to 1.35.

ASML offers the following immersion systems:

The TWINSCAN NXT:2050i which is a tool designed for volume production of 300 mm wafers at sub 5 nm nodes.

The TWINSCAN NXT:2000i for manufacturing the sub-7nm Logic and advanced DRAM nodes.

The TWINSCAN NXT:1980Di for volume production at sub-10 nm nodes.

The TWINSCAN NXT:1970Ci for volume production of 300 mm wafers at the sub-20 nm nodes.

Dry systems

The less complicated layers on a chip can be printed using older technology such as dry lithography systems.

ASML has a dry systems product portfolio which offers cost-effective solutions for their customers. These machines are less expensive to purchase and maintain.

ASML offers the following dry systems:

The TWINSCAN NXT:1470 - the latest ArF lithography system, offering a productivity of 300 wafers per hour with a 4 nm overlay capability.

The TWINSCAN XT:1460K - ArF lithography tool designed for volume 300 mm wafer production at 65 nm resolution.

The TWINSCAN XT:1060K - ASML’s most advanced KrF lithography system.

The TWINSCAN XT:860N - ASML’s new-generation KrF system, supporting high-volume 200 mm and 300 mm wafer production at and below 110 nm resolution.

The TWINSCAN XT:400L - designed for volume production of 200 mm and 300 mm wafers down to a 220 nm resolution.

Metrology and inspection systems

The third important segment is metrology and inspection.

These systems allow chipmakers to measure the patterns that they print on the wafer and how well they match the pattern that was originally intended.

They offer automated control loops by:

supplying process control solutions,

optimizing the lithography system settings for each exposure to reduce the edge placement error (EPE),

enlarging the process window to achieve the highest yield and best performance in mass production.

ASML offers optical metrology, e-beam metrology, system and process control and computational lithography.

This pocket of the business contributed 2.8 per cent of revenue in 2021.

Optical metrology

ASML’s YieldStar optical metrology solutions allow chipmakers to assess the quality of patterns on the wafer in volume production, through the so-called overlay measurements.

Simply put, overlay is how well one layer of a chip is aligned with the previous one.

It is an important measure of lithography performance and a key contribution to EPE.

As structures on microchips get smaller and smaller, overlay and EPE become more and more important.

ASML offers the following optical metrology systems:

The YieldStar 385H which is the latest post-lithography (pre-etch) overlay and focus metrology.

The YieldStar 1385H which provides the ability to measure after-etch device patterns and enables yield control capability.

The YieldStar 1375F which is the first YieldStar optical metrology system to offer measurements within the chip itself by measuring multiple layers at once.

The YieldStar 380G is an optical metrology system that offers monitoring of on-product overlay and focus performance.

E-beam metrology and inspection

ASML’s e-beam solutions help locate and analyze individual chip defects.

ASML offers the following here:

HMI eScan 1100 which is up to 600 per cent faster than previous e-beam wafer inspection tools, thanks to its multibeam technology, high-speed wafer stages and advanced computational algorithms.

The eScan 600 which is a highly flexible e-beam wafer inspection system operating in multiple modes and allowing chipmakers to capture different defect types in a single system.

The eScan 430 which is ASML’s latest single-beam inspection system, delivering more than 35 per cent throughput improvement across various applications in Logic, DRAM and 3D NAND.

The eP5 is ASML’s high-resolution e-beam metrology system. ASML also released an EPE metrology application software product on eP5.

System and process control

ASML also offers system and process control software products that enable automated control loops to keep lithography processes operating optimally.

By using algorithms, they analyze metrology and inspection data and calculate necessary corrections for each individual exposure. These then can be fed back to the lithography system to minimize edge placement error in subsequent wafer lots.

Computational lithography

Computational lithography solutions are another critical piece of the puzzle.

They are used in the development of new chips to optimize reticle patterns and the setup of the lithography system to ensure designs that deliver high yields.

Insights from computational lithography solutions are also used to guide metrology and inspection and:

increase throughput

enable more precise process monitoring and control in high-volume manufacturing.

Services

Services are also a big deal, bringing in almost a third of the total revenue.

ASML offers an extensive installed base management portfolio, including a wide range of service and upgrade options.

The refurbishment from the company’s engineers who take the machines apart and put them back together in blue cleanroom suits is robust.

Proof: 90 per cent of the systems sold in the nineties are still in use today.

ASML also develops and sells product options and enhancements designed to improve throughput, patterning performance and overlay.

ASML also supports customers with a broad range of applications, services, and technical support products.

It has almost 7,000 customer support employees, offers 24/7 support, next-day parts delivery, a centralized customer portal, and training for customer engineers.

In 2021, the customer support organization has provided nearly 5,000,000 hours of customer support, up from 4,500,000 hours in 2020.

Okay, we made it through the enormous range of products and services.

To be honest, I’m not sure if you can be better diversified than ASML.

It’s just textbook. Money is coming in from all angles and from all parts of the globe.

The scale is preposterous.

And it takes almost 2,000 words and a glossary of terms just to explain what they are selling.

But how such a beautiful intricate web of products and services translates into growth, value, fundamentals and momentum?

***

As you will see below:

Growth is vigorous and projected to continue climbing.

ASML is not cheap but following the brutal tech sell-off, the price sits at a historical low from the standpoint of a few key metrics.

Fundamentals are strong with just a few, almost imperceptible glitches in the machine.

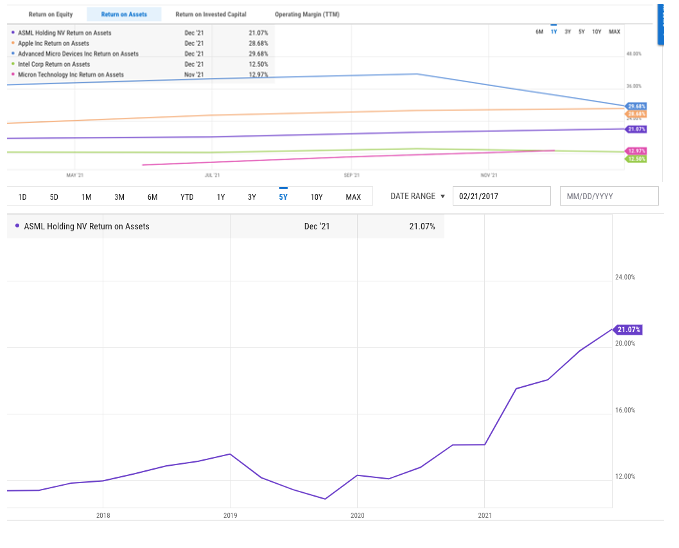

2021 was a breakthrough year in many respects but especially when you look at the return on invested capital, operating margin, return on assets and cash from operations.

Momentum seems to be slowing.

Hedge funds are (moderately) buying.

Growth Metrics

You have probably heard the tired cliché that everything that isn’t growing is dying. Yet, it is still a useful north star for investors.

And ASML has proven over the years that it can steadily increase revenues and squeeze out greater margins in the process.

Revenue

So let’s now dive into ASML’s top line.

The company has enjoyed robust revenue growth in the last few years.

It has more than doubled its sales from the 2017 level of €8.9 billion to €18.6 billion in 2021.

In 2021, year on year growth hit 33.14 per cent.

The forecasts look just as sweet.

ASML expects 2022 to be another year of strong growth with a net sales increase of around 20 per cent relative to 2021.

The Dutch giant posits that such healthy growth will be driven by increased sales on all its platforms.

In particular, strong tailwinds include:

Logic demand

Growth in the Memory market and

Growth in the installed base business.

The company also sees that there will be positive industry momentum around innovation and the expansion into new markets.

Wall Street analysts predict that revenue will hit €27.3 billion in two fiscal years ahead.

Based on the different market scenarios, ASML estimates to have an opportunity to reach annual sales between approximately €24 billion and €30 billion in 2025, with a gross margin between approximately 54 per cent and 56 per cent.

So, in a low market scenario, we are looking at 3-year revenue growth of 29 per cent.

In a high market scenario, the revenue is predicted to grow at 61 per cent.

Not bad.

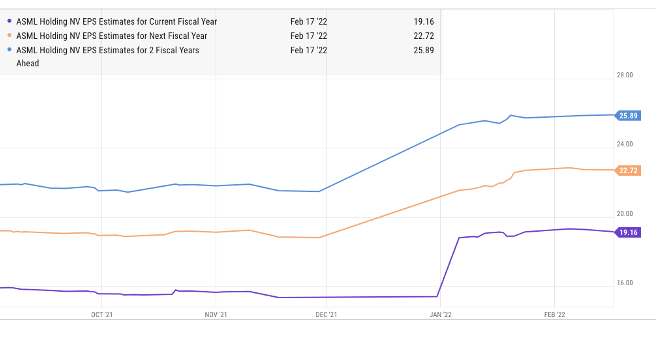

One small, almost imperceptible glitch here is the minor downward revision of revenue estimates for the current and next fiscal years (chart below).

Earnings Per Share

In 2021, net income amounted to €5.8 billion (or 31.6 per cent of total net sales), translating into basic net income per ordinary share equaling €14.36.

This is a big spike relative to 2020 when net income came in at €3.5 billion (or 25.4 per cent of total net sales) and basic net income that amounted to €8.49.

So in 2021, basic EPS grew 75.24 per cent year-over-year.

And Wall Street (or 15 analysts covering the company to be exact) predicts that the climb will continue.

EPS estimates for two fiscal years ahead sits at €23.65.

When it comes to the average rate of earnings growth for the next 3-5 years, the estimates have fallen recently from 26 per cent to 21 per cent.

While it is difficult to discern the reasons behind the fall, it is one of the very few hiccups in the growth engine.

While the EPS LT Growth is typically estimated by a lower number of analysts and 21 per cent is still healthy, it is important to remember that this metric is quite magical.

It is highly correlated with the long-term performance of a stock, so it is vital to observe its trajectory closely as we go forward.

Operating Margin

2021 was one hell of a year for AMSL’s operating margin.

Operating margin measures the proportion of revenue left over after paying the variable costs of production.

It is an important indicator of both efficiency and profitability, as it demonstrates whether the management is effective in either maintaining costs or increasing revenues.

As you can see from the chart below, since 2012 the picture was mixed in this respect; and we could observe an up and down pattern (albeit a healthy double-digit margin throughout).

However, in 2021 operating margin broke out and hit a record high of 35.12 per cent (up from 28.98 per cent in 2020), placing it on top of the semi food chain.

This increase is mainly attributable to the NXE 3600D and DUV immersion systems value proposition and continued growth in the installed base business.

ASML continues to drive the profitability of their EUV systems and, as a result, achieved a 50 per cent system gross margin in 2021.

Looking ahead, ASML claims it will continue to seek improvements in the margins in both systems and service through:

cost reduction and

delivering more value leading to higher prices.

Return on Assets

The rate of return earned on all of the firm's assets basically measures how efficiently the company is using assets to earn returns.

ASML’s ROA was essentially flat for a decade before doubling in 2021.

Value Metrics

We all know that the purchase price matters.

And as you may have already guessed, purchasing a linchpin in the semiconductor supply chain will naturally entail paying a premium.

ASML is by no means cheap, trading at 35 times earnings.

However, the recent brutal sell-off in tech stocks has made it more attractive.

In fact, the price target upside is currently at a historical high, smoking even the March 2020 nadir (twice) with a whopping 54 per cent upside.

As you can also see from the charts below, all the typical value metrics such as the Price to Sales Ratio, Price to Book Value, Enterprise Value to EBIDTA and Price to CFO Per Share are nearing their 5-year median levels, signaling a decent time to buy.

Cash from Operations

If you read my previous post on Bridgewater, you may recall the most important sentence from it. Cash flows are the dominant force on returns over time.

It is certainly not the discount rate everyone obsesses over.

So, a reliable rising cash flow regardless of the economic environment is king.

Vertical CFOs truly are the holy grail of investing.

Now ASML’s cash from operations was admittedly fairly flat over the last years.

However, in 2021 it just went through the roof in a vertical fashion, hitting over $12 billion.

Fundamentals

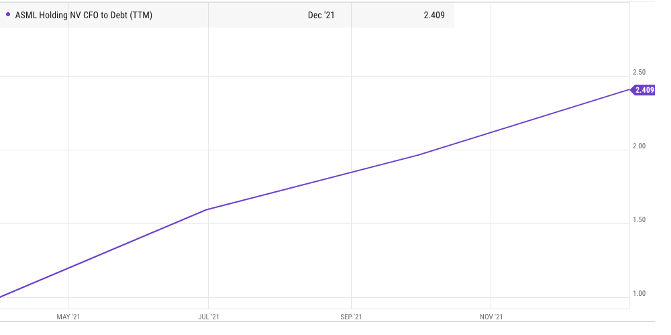

CFO to Debt

When you look at how long it would take for AMSL to repay all of its debt, if they used their cash flow from operations, a picture of serious financial health emerges.

From this standpoint, their whole debt would be gone in less than six (!) months.

Ohlson Score

Now, let’s look at the firm’s likelihood of bankruptcy.

The Ohlson Score uses different approximate measures of a firm's default risk, such as the company’s size, leverage, working capital, liquidity, profitability, change in net income, and debt financing.

Results greater than 0.5 indicate that a firm has a higher chance of a default.

While the safest companies sit below zero, ASML’s 0.136 score is still decent, pointing out that a risk of a default is unlikely.

Times Interest Earned

And what about ASML’s ability to meet debt obligations based on its current income.

The formula used here is earnings before interest and taxes (EBIT) divided by the total interest payable on debt.

The result is a number that shows how many times a company could cover its interest charges with its pretax earnings.

ASML comes correct with a stupendous figure of 151.

So strong.

Return on Invested Capital

As the illustrious Berkshire Head Honcho, Warren Buffet once said “the ideal business is one that earns very high returns on capital and that keeps using lots of capital at those high returns. That becomes a compounding machine. But there are very, very, very few businesses like that…”

So clearly ROIC is an important measure. It gives you an idea how much net income has been generated per each dollar of invested capital.

Typically, capital intensive companies do not shine in this field.

Yet, ASML’s story here is anything but clear-cut.

If you go back in time to 2012, ROIC has had a u-shaped trajectory with mid-teens throughout the years (and a 5-year median of 17 per cent) followed by a stunning spike from 2020 onwards.

If ASML could maintain the current astounding 35 per cent ROIC level, it could well enter this narrow circle of dream compounding machines, despite the capital intensity of its business.

Debt to Assets

So how much debt ASML has on its balance sheet relative to total assets?

In this case, ASML’s long term and current portion debt amounts to only 15 per cent.

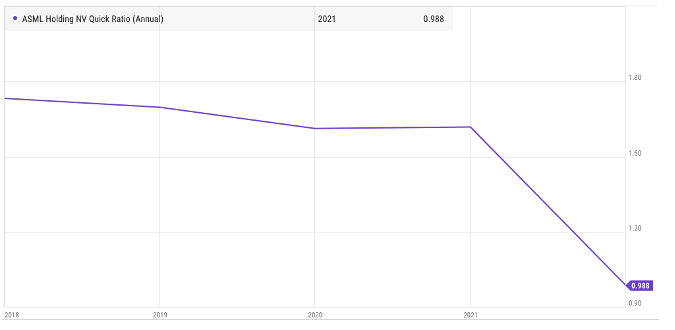

Quick Ratio

Looking at solvency from a different angle, we can determine whether ASML has the ability to pay down current liabilities with its cash, short term equivalents, and accounts receivables.

Typically, a result of 1 is considered to be normal, as it shows that the company is fully equipped with enough assets it can instantly make liquid to pay off its current liabilities.

A company with a quick ratio of less than 1 may not be able to do this in the short term.

ASML just misses the mark here with 0.98.

Again, a rare glitch in an otherwise robust set of fundamental metrics. (Also, as a note of caution, different data sets provide different numbers and in certain instances the quick ratio is quoted to be above 1).

Momentum

In financial markets, momentum is defined as the tendency of assets that have gone up in price to continue going up in price.

Or the reverse. If they have been going down, they will continue to do so.

The Momentum Score is a system that assesses companies based on their one year total returns, excluding the last month of returns.

The curious case of ASML is that its price peaked in September 2021 and has been, more or less, declining since. It has now fallen to March 2021 levels (you can see the M-shaped chart below).

So if you look at a full year, the price has essentially gone nowhere.

Naturally the momentum score followed suit and dropped from 9 to 8.

Risk

As with every investment, we also need to look at risk. In particular, if you would wish to determine the proportion of ASML’s shares in a particular portfolio.

Sortino

The Sortino Ratio measures the risk-adjusted return of an asset by calculating the average return earned in excess of the risk-free rate per unit of volatility.

What’s interesting about it is that it only considers the standard deviation of the downside risk, rather than that of the entire (upside and downside) risk.

Because of this, it is considered to give a better view of a portfolio's risk-adjusted performance given that positive volatility is a benefit.

ASML’s Sortino Score is robust (2.6) pointing to solid risk-adjusted returns.

Value At Risk (VaR)

The VaR calculates the potential loss of an investment with a given time frame and confidence level.

ASML has a 5 per cent Monthly VaR (All) of 18.53 per cent which means there is 95 per cent confidence that the security will not have a larger loss than 18.53 per cent in one month.

Percent Off All-time High

This metric tells you how far the price has deviated from on the all-time high price.

As you can see below, it is also at a historical low.

Research and Development

If you read Philip A. Fisher’s Common Stock and Uncommon Profits (which is highly recommendable), you may recall the importance of effective research and development efforts relative to the company’s size.

(NB: What is interesting is that Ken Fisher who is the author’s son is the 4th largest institutional investor in ASML).

Now, as already mentioned, ASML’s stupendous R&D spending has been responsible for hammering out EUV.

And now they just keep blazing forward.

After five years of engineering, they started to build the next generation EUV lithography systems with a higher numerical aperture (NA) of 0.55 relative to the current 0.33 NA.

EUV 0.55 NA will offer a higher resolution and, therefore, enable even smaller features and increased density.

ASML expects this technology to be critical to affordable scaling well into the next decade and anticipates that it will enter high-volume manufacturing in 2025–2026.

Conclusion

So, to conclude:

ASML sells machines which generate light you can only find in space to pattern the finest details on the most sophisticated chips.

Its EUV technology is so advanced that the company enjoys an insane moat and is essentially a monopoly.

The future of exponential digitization and the pursuit of Moore’s law pretty much rest on this stand-alone linchpin, making it one of the most important companies no one has ever heard of.

ASML has very competent management that is able to increase revenue and squeeze out profit.

It has a healthy culture, with growing, talented, thriving and long-serving staff.

Growth is vigorous and the climb is projected to continue.

ASML is not cheap but following the brutal tech sell-off, the price sits at a historical low from the standpoint of a few important metrics. In fact, one could risk the supposition that there seems to be a disconnect between the underlying business and the price movement in the past year.

Fundamentals are strong with just a few glitches in an otherwise robust business machine.

2021 was a breakthrough year in many respects but especially when you look at the return on invested capital, operating margin, return on assets and cash from operations.

Momentum seems to be slowing.

Major headwinds include geopolitical tensions, swift decoupling, Russia’s-invasion-induced pressure on supply chains and IP technology leadership pressure.

***

Finally, if you have not checked out Invest Like the Best hosted by the great Patrick O’Shaughnessy, I highly recommend it.

Recently he spoke to John Pfeffer whose trajectory in the world of investing will blow your socks off.

So, I decided to conclude by extracting a canonical checklist he uses to determine whether a business is good and see how ASML stacks up against it.

And while capital intensive companies would appear to have low chances of succeeding against the backdrop of criteria favouring tech high-flyers, ASML fares pretty damn well here:

So, would you buy the stock if someone you love dearly had to rely on it for retirement?

Disclaimer/Disclosure: This is not investment advice. This post is for educational purposes only.